Storage Enclosures

Microfilm is wound around a reel or core. Winding too tightly increases the risk of scratching; microfilm wound closer than 1/4" to the outer edge of the core can slip off. Both the core and the container must be made of a non-corroding material like anodized aluminum, stainless steel, peroxide-free plastic, or acid-free paper.

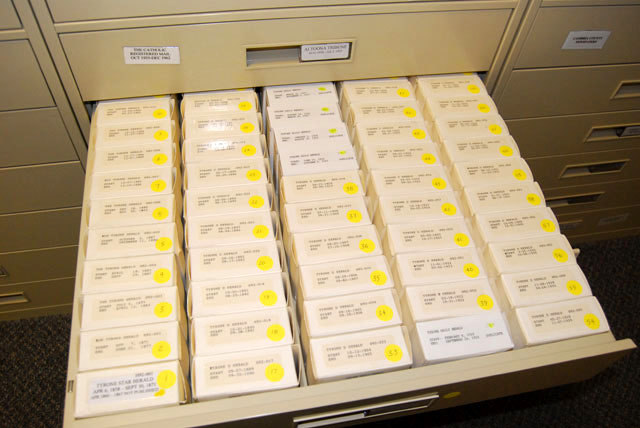

To achieve the greatest protection, the microfilm roll should be placed in a sealed, airtight container to protect it from dust, gaseous impurities and moisture. Optimal storage for microfilm rolls is in single reel storage boxes, with film held in the wound position by a preservation-quality paper tag secured with a string and button tie. Steel filing cabinets are preferable for microform storage, but inert plastic containers are acceptable for library shelf use.

Microfiche should be sleeved with the emulsion side away from the interior enclosure edges to prevent abrasion. Microfiche enclosures should fit without buckling into drawers, with space dividers to prevent curling. Dividers and placement guides should be made of pH neutral materials.

ANSI/NAPM IT9.11-1993 and ANSI/PIMA IT9.2-1998 specify exact conditions for archival storage of film.

Relative Humidity and Temperature

Both relative humidity and temperature in the storage environment should be rigidly controlled, with variations no greater than 5% in 24 hours.

Relative humidity should be kept within a range of 30 to 40% to protect polyester film base. Cellulose base film can be stored safely in humidity as low as 15 %.

Low relative humidity causes microfilm to dry out and become brittle. Under high relative humidity, the emulsion layer absorbs moisture and either expands resulting in distortion of the image, or the film surfaces stick together. Microscopic redox blemishes are also likely to form on silver-gelatin films from oxidation above 40% RH.

Ideal storage temperature is less than 70-F, ideally 65-F. Master films should be stored at maximums of, 35% RH, +/-5%.

High temperatures cause the microfilm base to shrink and buckle, whereas low temperatures cause brittleness.

A thermograph and hygrometer will allow temperature and relative humidity to be monitored. Long term preservation is an ongoing practice in which random samples of microfilm (1 to 2%) should be inspected for damage every alternate year. Guidelines for inspecting silver gelatin film are offered in ANSI/AIIM MS45-1990. Signs of deterioration include discoloration, blemishes, evidence of oxidation reduction (redox), fogging, fungus, buckling, brittleness, faded images, and adhesion, for which immediate corrective action is required.

Rapid transfer from a cold to a warm space may cause water condensation on the surface of microfilms. A transitional period is required to allow the gradual warming of cold microfilms when moving microfilm out of storage facilities to readers.

Pollution

The air in the storage facility should be filtered to remove gaseous impurities such as sulfur dioxide, hydrogen sulfide, ammonia, peroxides, ozone, nitrogen oxide, formaldehyde, paint fumes, and solid particles like dust. Silver-gelatin films are susceptible to abrasion by particulate matter. Gaseous air pollutants cause microscopic blemishes on silver-gelatin films.

Silver-gelatin films should be stored in a different location from diazo or vesicular microfilms. Fumes from degrading diazo or vesicular microfilm may damage silver gelatin microfilm.

The fire suppression system installed in the storage room should use halon not water.

Multiple Copies

Implementation of a three-generation system is recommended for protecting the original master negative microfilm.

Master Negative

The first generation film (or master negative) should be a silver-gelatin negative produced from the original artifact and processed according to standards given in ANSI/AIIM MS23-1998. The master negative should be stored in a different location from secondary copies, and in storage conditions that meet ANSI standards outlined in ANSI/NAPM IT9.11-1993. The master negative is an archive protected for the purpose of preservation.

Duplicate Negative (or Print-Master Negative)

The duplicate negative, usually of silver-gelatin, should be stored under optimum conditions since it serves as a working master, and is used to generate use copies for the collection. Ideally, it should be physically separated from use copies.

Use Copies (or Service Copies)

Any of the available media or formats may be acceptable, and images may be positive or negative. Good storage and handling will extend the life of use copies, thus protecting previous generations of microforms.

Source: Northeast Document Conservation Center. (2000). Microfilm and microfiche. Retrieved February 25, 2011, from http://www.nedcc.org/resources/leaflets/6Reformatting/01MicrofilmAndMicrofiche.php

Source: South Carolina Department of Archives and History, Archives and Records Management Division. (1992). Microfilm storage. Retrieved February 25, 2011, from http://arm.scdah.sc.gov/NR/rdonlyres/2AB351B6-0473-4C56-9420-B90A6B0FD29B/0/ELEVEN.PDF